Almost 60 % of greenhouse gas emissions, caused by humans, come from burning fossil fuels for electricity production and transport. The resulting decrease in energy sources is a major challenge. However, the alternatives, like solar and wind power, differ a lot in their local and temporal supply. Times of low generation alternate with times of local overproduction, when the grid cannot absorb large supplies of solar power and/or wind power. This results in a great need for storage, especially of electrical energy. Approaches for this, besides storage in batteries, are seen in electrolysis for hydrogen production. Although hydrogen appears to be an ideal energy carrier with regard to an emission-free energy supply, it requires very complex and expensive storage systems due to its extremely small atomic size. Furthermore, it is also economically inefficient to convert hydrogen back into electrical energy because the required fuel cell technology to do so, is very expensive.

Sewage treatment plants can also function as energy producers: the generation of electricity from sewage gas in combined heat and power plants serves as a self-supply of electrical energy. At some times, however, the supply of other renewable energies in the electricity network is so high, that their use at the sewage treatment plant can be used in chemical energy storage concepts in a way, that makes sense for the economy as a whole. One option here is to turn sewage gas/biogas into a liquid energy source like methanol. In addition, it is possible to include electrolytically produced hydrogen and carbon dioxide (CO2), which may come from other sources, into the synthesis process. Methanol has many advantages:

- easy storage and high energy density

- very flexible and uncomplicated usability as fuel and chemical raw material

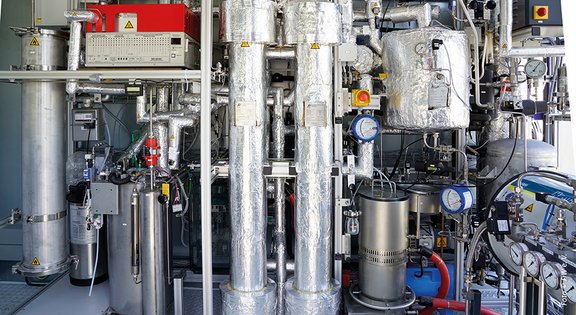

As part of the pilot project "WASTRAK NRW - Use of Hydrogen Technology in Wastewater Disposal", funded by the state of North Rhine-Westphalia (NRW), a semi-technical plant for methanol synthesis from biogas was realised and operated.

Pre-cleaned biogas (feed gas) is separated (also called reformed) into synthesis gas (hydrogen, carbon dioxide and carbon monooxide) in a reformer with the help of steam. A partial flow (fuel gas) is burned together with air in order to supply heat for the reforming reaction. Afterwards, the catalytic synthesis of methanol takes place. This happens in the samer reactor, so the synthesis gas produced before, is now changed into methanol. The design for operation at lower pressures of 20 and 22 bar is well below the normal industrial scale of 50 to 100 bar. These conditions simplify the operation and applicability of the process, e.g. at a biogas production location. An innovative key element of the process is the highly efficient internal heat transfer and the recycling of the material flow to maximise the product output. A programmable logic controller (PLC), which allows different test procedures, controls the test technology.

With the pilot plant, it could be shown that the technical challenge of methanol synthesis, including the recycling of the unreacted gas components, could be managed. This was achieved in particular by combining the necessary heating and cooling processes and so making full use of the existing energy potential of the educts, products and by-products of the plant. To collect the product, consisting of a methanol-water mixture, it was condensed out in a subsequent process stage.