Power-to-Fuel

New processes for the production of climate-neutral energy sources based on biogas and renewable surplus electricity

In view of ambitious national and international efforts to reduce the anthropogenic climate change as far as possible in the coming decades, renewable and biogenic energy sources (RES) have become increasingly important in recent years.

Due to the constant funding and subsidisation, renewable energies have become an essential, supply-determining part of energy production, especially in the electricity sector. Large generation capacities are required for fluctuating electricity suppliers such as wind and solar power plants. This inevitably leads to the fact that compensatory measures must be taken more frequently at all levels of the electricity grid in order to compensate for performance deficits or surpluses and to guarantee the functionality and technical service life of the plants. In recent years, research has increasingly focused on various storage options in order to avoid regulating renewable plants and thus leaving parts of the energy potentially generated by RE plants unused. Water electrolysis is currently considered a key technology for the efficient storage of excess electricity. In the German government's Climate Protection Plan 2050, it is named as an essential component for achieving the greatest possible climate neutrality for Germany.

The driving forces in this context are, the constantly rising energy costs, which encourage energy savings and measures to increase efficiency, and the possibilities for using the energy potential to cover one's own electricity and heat requirements. In addition to energy supply and use, the focus is also on climate protection and the avoidance of anthropogenic greenhouse gas emissions.

When considering future energy supply systems, the focus is increasingly on the utilisation or storage of (surplus) energy in addition to conventional electrical energy supply. Against this background, FiW is currently working on several projects dealing with the storage of renewable energy and the reduction of CO2 emissions.

Since coal-fired power plants in the Rhenish mining area are about to be shut down, the focus will increasingly shift to waste utilisation plants, which then overtake the title as biggest emitters of CO2. At the same time, however, they offer an outstanding CO2 source for innovative technologies for sector coupling.

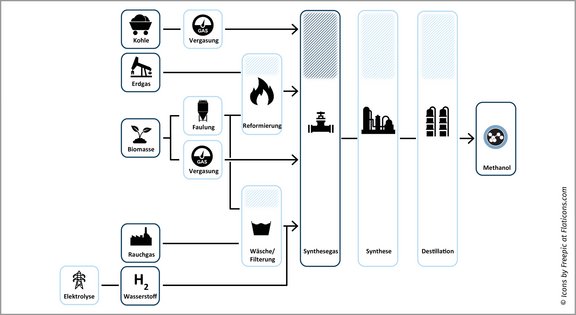

One innovative technology for sector coupling is the binding of CO2 from exhaust gases of waste incineration plants and its subsequent reaction with H2 to form a green fuel: methanol. By using methanol synthesis, far-reaching synergies for the use and storage of renewable energies, reduction of CO2 emissions and power-to-product can be achieved.

Given that a widespread introduction of battery electric vehicles and vehicles with fuel cell drive does not seem to be feasible in the near future, the further development of the combustion engine and its operation with environmentally friendly clean fuels from renewable energies could become increasingly important. The waste incineration plant in Bonn offers ideal framework conditions for increasing these potentials.

In this context, options are being examined for separating CO2 from the exhaust gases of the incineration plant using CCU (Carbon Capture and Utilisation) processes and transforming it into chemical products with the help of innovative synthesis processes. All in all, a concept will be developed in the coming years which foresees the economically and ecologically sustainable production of a CO2-based resource on an industrial scale. Within the cooperation, this enables the development of a long-term and sustainable concept for the Bonn waste incineration plant site.

Customer: Müllverwertungsanlage MVA Bonn GmbH

In water management, wastewater treatment plants are characterised both as energy consumers and producers. When considering future energy supply systems, the focus is increasingly on the utilisation or storage of (surplus) energy in addition to conventional electrical energy supply. Independent of many development and optimisation efforts of available components, a special need is detected in the networking of the entire energetic infrastructure, the interaction of individual components and the provision of regenerative energy sources. In this context, wastewater treatment plants offer favourable conditions and special synergy effects for the interconnection of different technologies.

FiW began investigating alternative concepts for energy storage in 2010 within the framework of the project "Use of Hydrogen Technology in Wastewater Disposal" (WaStrak) funded by the NRW Environment Ministry.

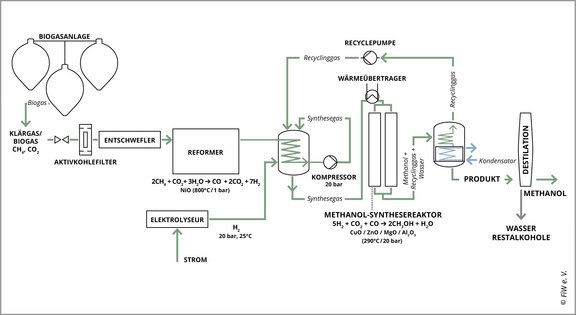

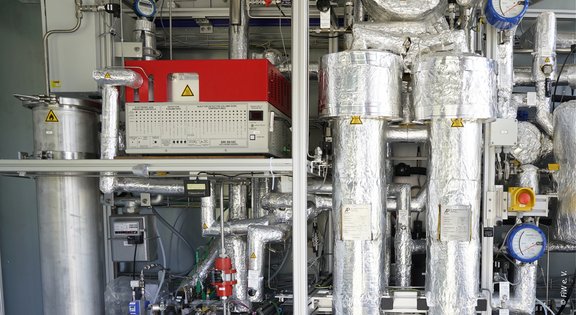

This has resulted in a pilot plant in which the sewage gas is further utilised via steam reforming and catalytic reaction to produce methanol, a higher-value liquid energy carrier. By means of this project, the feasibility of this recycling approach on a pilot scale was demonstrated. Based on the results obtained in the WASTRAK project, FiW is working together with OWI on the optimisation of the synthesis plant and thus on the elaboration of a plant concept ready for marketing.

The research on the existing plant relates to several key issues:

- Development of an extended reforming process for biogas

- Integration of an electrolyser

- Extension of the synthesis process by one distillation stage

- Improvement of the synthesis reactors

- Optimisation of the process and process parameters

All in all, the individual optimisations are aimed at producing high-purity methanol with the demonstrator. This represents an alternative, high-quality use of sewage and biogas, which provides an economical alternative to the use of the gas in a combined heat and power station. In addition, a closed plant concept is to be developed which allows an ecological scaling of the plant size and thus has the potential to be marketed to producers of digester gas in the future.

Customer: Federal Ministry of Economics and Energy

Project owner: EURONORM GmbH

Project partner: OWI Science for Fuels gGmbH

In the context of the Methanol Standard research project, the technical basis for standardising methanol fuels in Europe will be investigated. In addition to standardisation, an essential component of the research project is the optimisation of the Otto engine combustion concepts. Fuel production, safety-relevant features such as flame visibility and toxicity and methanol production will also be investigated within the research project. It will be examined whether the IMPCA standard for methanol, which is already used in shipping, can be used directly for road transport applications or whether an additive is required to achieve a safe cold start and material compatibility. First, investigations will be carried out on a single-cylinder engine and these results will then be implemented on a prototype engine. Another option for the use of renewable methanol in transport to reduce overall carbon dioxide emissions is methanol-gasoline (M15) blends, which will be investigated as "drop-in" fuels in future series production engines and higher blends in flex-fuel engines. This offers a short-term opportunity to decarbonise road traffic. A possible sector coupling and the creation of synergies with maritime transport will be discussed.

FiW is supporting this large collaborative project, particularly with regard to the issues of production routes for green and sustainable methanol synthesis and its life cycle assessment. In this context, the production of "green" methanol from CO2 is being investigated in experiments and optimised with numerical calculations. Furthermore, potentials for a scale-up are evaluated.

The normative need for action for a comprehensive introduction and application of a standardised methanol fuel is to be determined through a holistic technical, economic and ecological approach.

Customer: Federal Ministry of Economics and Energy

Project owner: TÜV Rheinland Consulting GmbH

Project partners: V Europe GmbH; Bayerische Motorenwerke Aktiengesellschaft; TEC4FUELS GmbH; Ford-Werke GmbH; Liebherr-Components Deggendorf GmbH; ASG Analytik-Service GmbH; Oel-Waerme-Institut gGmbH; Lehrstuhl für Verbrennungskraftmaschinen der RWTH Aachen