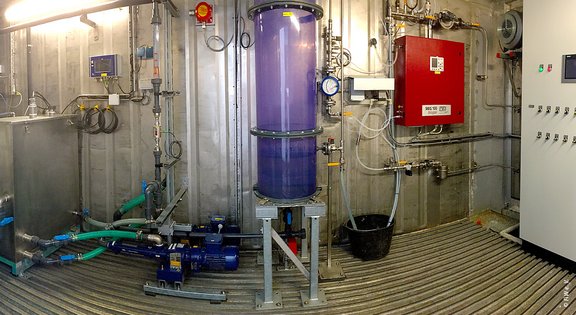

Pilot plant for microbiological biogas desulfurization

Development of an innovative biogas desulfurization process that ensures subsequent energetic use in combustion processes in an economical and environmentally friendly manner

Biogas, an energy-dense combustible gas, is the end product of the anaerobic decomposition of organic matter. The main component of biogas is methane (CH4), which can be used in combustion engines for energy generation. In addition to methane, however, biogas also contains large amounts of carbon dioxide (CO2) and other associated gases. Hydrogen sulfide (H2S), which is particularel problematic, is primarely formed during the conversion of protein-containing substrate. Here, H2S concentrations of 200 to 5,000 ppm (0.02 to 0.5% by volume) can frequently occur in the biogas produced.

Combustion of H2S produces sulfur dioxide (SO2). SO2 acts as a greenhouse gas in the atmosphere. At the same time, it causes damage to gas engines through corrosion and lubricant acidification. Many devices for catalytic exhaust gas purification are limited in their function by sulfur oxides (SOX). In addition, H2S has a highly toxic effect on many organisms even in very low doses.

Current aspects, such as the steady tightening of legal emission requirements and the need for energy optimization, require the innovative development of biogas purification, especially the removal of hydrogen sulfide. The use of a biological-oxidative purification process represents a sustainable and holistic approach to biogas desulfurization in order to guarantee the intended efficiency for biogas engines and low-maintenance operation without shortening runtimes.

Process description

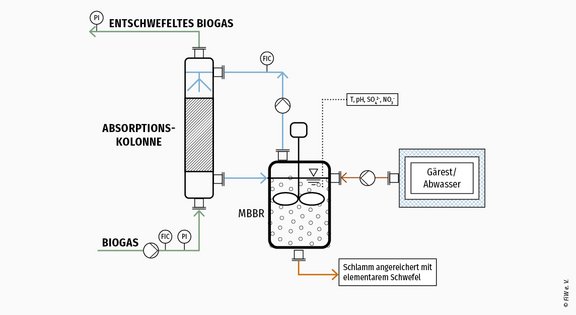

As part of the ZIM funding program of the German Federal Ministry for Economic Affairs and Energy (BMWi), the innovative Nitro-SX desulfurization process was designed and a test plant was planned and built to microbiologically reduce the H2S content of biogas. For this purpose, the plant is operated with digestate and biogas from an agricultural biogas plant in order to study realistic and practical operating conditions. Naturally occurring microorganisms as well as nutrients from the digestate are used, which convert reduced sulfur compounds for energy production (chemolithotrophic bacteria). During biological desulfurization, these strains are used to degrade H2S in the biogas together with nitrate (NO3–). The conversion occurs stepwise via elemental sulfur to sulfate. The energy obtained is required for metabolism and growth.

The experimental plant consists of a biogas countercurrent absorption column with a connected moving bed bio-reactor (MBBR) to validate the framework conditions for process engineering. The experimental plant incl. measurement and control technology (MSR) was manufactured in a compact containerized design in cooperation with the companies EvU Innovative Umwelttechnik and aquatec-Reuter.

Outlook

Within the framework of the follow-up project, which is currently running until July 2022 and is funded by the BMWi via the Inno-Kom funding guideline, the process should be further developed. The aim of this follow-up project is to generate a deeper understanding of the microbiological phenomena via long-term tests, as well as to bring the Nitro-SX process to a level of market maturity that allows operators an economical and environmentally friendly option for construction and operation. In this consideration, both energetic and process engineering questions are to be answered. In particular, the following aspects will be worked out:

- Development of a large-scale plant concept including chemical calculations, reactor design and dimensioning of the associated components.

- Detailed concept development for the control and automation of the large-scale plant

- Monetary evaluation of the operational and process engineering aspects and scale-up of the process concept